Ask for informations

Sei interessato a questo prodotto? Vuoi un preventivo?

The new JET FC dust collector version is a ready-to-use system properly designed to ensure perfect filtration in all industrial processes where dusty residues originate. The thick galvanized sheet structure allows for both indoor and outdoor positioning, and it is suitable for operation in depression.

JET FC is available from 14 also up to 700 m2 of filtering surface in order to guarantee a wide range of models for all applications.

Jet pulse cleaning system is the most efficient way to keep the filter media clean during processing, preventing the powders from sticking the cartridges and clogging them. During daily processing, this type of cleaning system allows for a clean and fully efficient filter unit with no drops in performance.

This specific cleaning system is managed and controlled by an economizer, which optimizes the intervention times thanks to a differential pressure sensor to minimize the consumption of compressed air. The JET FC dust collector is suitable for processes that generate fine dust in the wood, plastics, chemical and metalworking industries.

The cartridges are of the highest quality and are made in different fabrics to be chosen according to the type of dust to be filtered. JET FC dust collector is always supplied pre-assembled in two parts for a practical and quick assembly.

This model can also be equipped with a pre-chamber intake which preserves and protects the filter cartridges, preventing the aspirated processing residues from settling immediately on the cartridges, clogging them. The pre-chamber distributes the air flow evenly over the entire filtering surface allowing residues to settle in the collection bin.

Prezzi Consulenza personalizzata

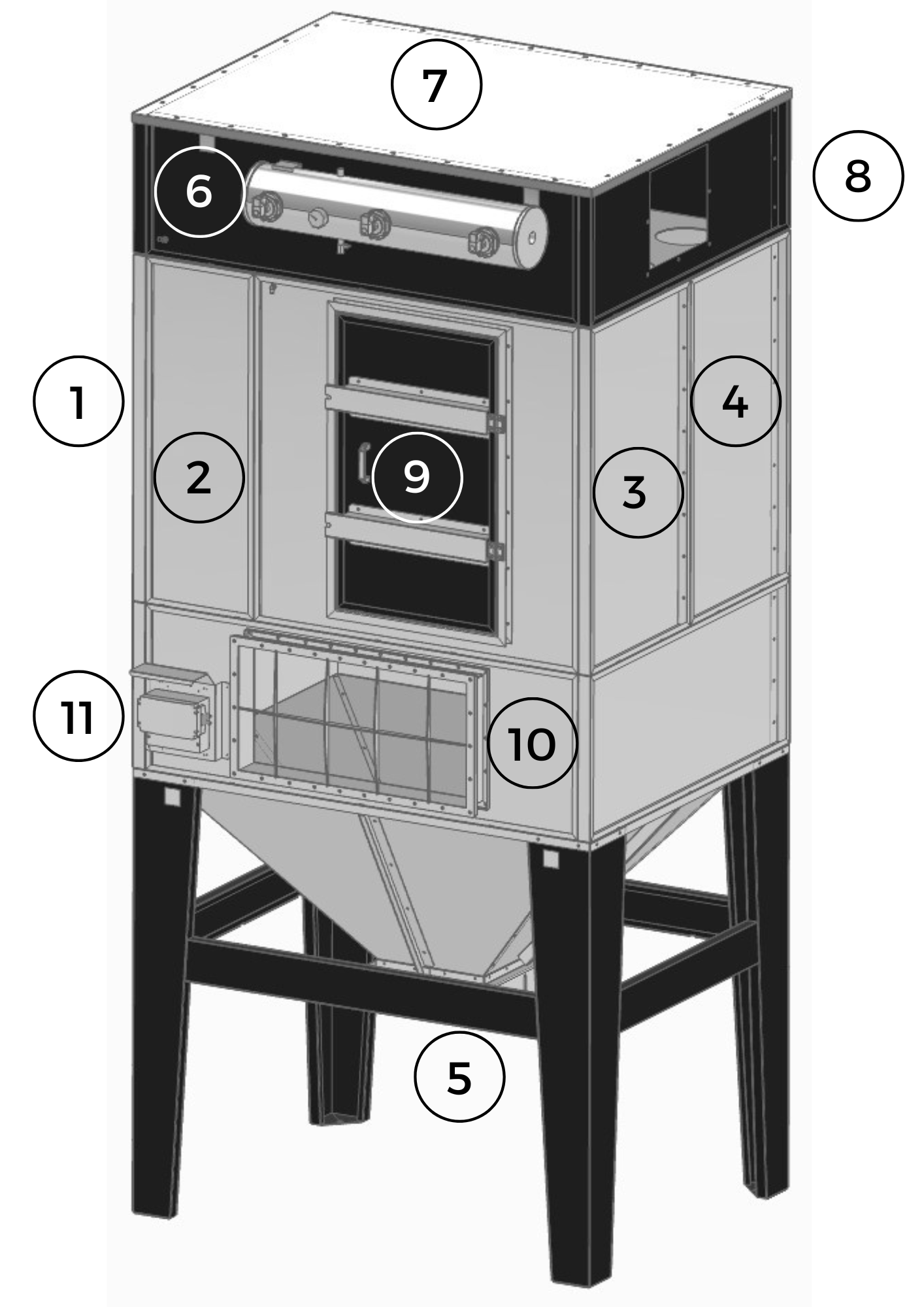

1. Dusty air inlet;

2. Pre-filtration chamber (Upon Request);

3. Filtration chamber;

4. Filtering cartridges;

5. Collection bin under the hopper;

6. Air tank for pneumatic cleaning system;

7. Plenum with venturi;

8. Clean air outlet;

9. Inspection and maintenance door;

10. Venting Panel (Upon Request);

11. Differential pressure switch.

| JET – FC | ||||||

| MODEL | Filtering Cartridges |

Filtering Surface |

Collection Bin |

Air flow* | Dimensions (only FC model) |

|

| n. x Ø 325 | m2 | n. | m3/h | l x p | h | |

| JET – 14 | 1 | 14 | 1 | 500 | 800 x 800 | 3.100 |

| JET – 28 | 2 | 28 | 1 | 900 | 1.00x 1.200 | 3.100 |

| JET – 48 | 4 | 48 | 1 | 1.700 | 960 x 960 | 2.800 |

| JET – 58 | 58 | 1 | 2.100 | 3.000 | ||

| JET – 73 | 6 | 73 | 1 | 2.600 | 1.400 x 960 | 3.100 |

| JET – 87 | 87 | 1 | 3.100 | 3.300 | ||

| JET – 109 | 9 | 109 | 1 | 3.900 | 1.400 x 1.400 | 3.100 |

| JET – 131 | 131 | 1 | 4.700 | 3.300 | ||

| JET – 145 | 12 | 145 | 1 | 5.200 | 1.900 x 1.400 | 3.100 |

| JET – 175 | 175 | 1 | 6.300 | 3.300 | ||

| JET – 194 | 16 | 194 | 1 | 7.000 | 1.900 x 1.900 | 3.300 |

| JET – 233 | 233 | 1 | 8.300 | 3.500 | ||

| JET – 242 | 20 | 242 | 1 | 8.700 | 2.300 x 1.900 | 3.300 |

| JET – 291 | 291 | 1 | 10.500 | 3.500 | ||

| JET – 350 | 24 | 350 | 2 | 12.600 | 2.700 x 1.900 | 3.500 |

| JET – 387 | 32 | 387 | 2 | 14.000 | 3.600 x 1.900 | 3.200 |

| JET – 466 | 466 | 2 | 16.800 | 3.400 | ||

| JET – 580 | 48 | 580 | 3 | 21.000 | 5.300 x 1.900 | 3.200 |

| JET – 699 | 699 | 3 | 25.000 | 3.400 | ||

* The Values “MAX AIRFLOW” refer to a crossing speed sleeves equal to 0.01 M/SEC.

Lower crossing speed provide better filtration and grater purity of the exhaust air.

Check the regulations of your country for the proper choice of the filtering unit.

Electrical Panel;

Discharge with rotary valve;

Soundproof box for motoventilator to lower the noise;

Staircase and walkaway to access the maintenance door;

Tank and control panel cover;

Pressure regulator;

Painted with a color chosen by the customer;

Fire prevention system with tubes;

Sprayer nozzles and temperature probe (Only ATEX version).

Certified electrical components: CE – UK CA – ULCSA – ecc.

Suitable for ATEX zone, with potentially explosive atmospheres and class ST1 powders according to the certification string II 3 D Ex tD A22 T200°C -10°C < T < 40°C.

Sei interessato a questo prodotto? Vuoi un preventivo?